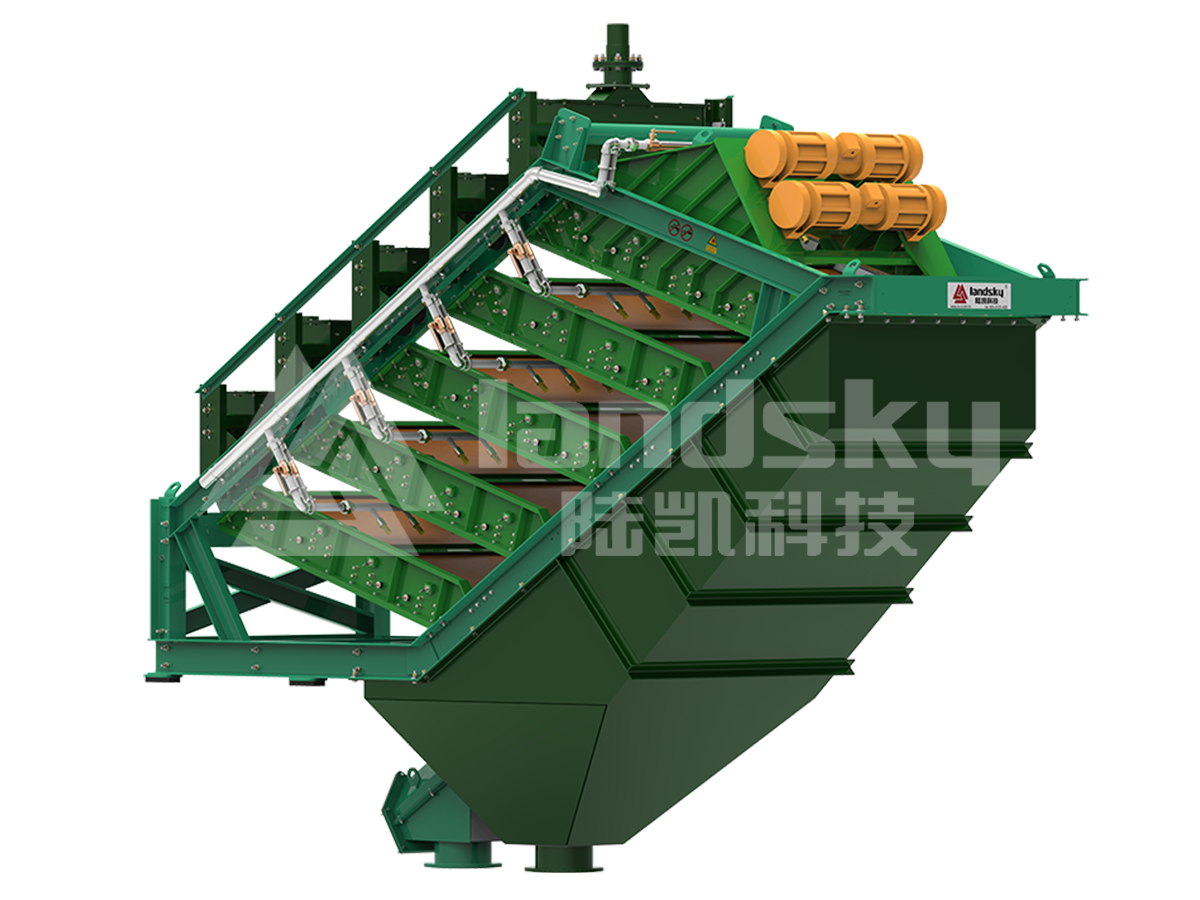

Muti-deck high frequency vibrating screen

Muti-deck high frequency vibrating screen

DxFG series laminated high-frequency vibrating fine screen box is arranged in multiple layers, independent feeding and independent screening. It has the advantages of small footprint, large processing capacity per unit area, high screening efficiency, low power consumption, small dynamic load, simple operation, stable performance, safety and durability, and low maintenance. It is mainly used for wet screening, grading, desliming, and coarse separation.

Muti-deck high frequency vibrating screen

DxFG series laminated high-frequency vibrating fine screen box is arranged in multiple layers, independent feeding and independent screening. It has the advantages of small footprint, large processing capacity per unit area, high screening efficiency, low power consumption, small dynamic load, simple operation, stable performance, safety and durability, and low maintenance. It is mainly used for wet screening, grading, desliming, and coarse separation.

TECHNICAL FEATURES

1. The screen box vibrates linearly, and the vibration excitation frame inside the screen box is elastically connected in the screen box, and is driven by the screen box to perform secondary near-resonant vibration. It realizes two vibration types which are linear vibration and excitation frame resonance self-cleaning vibration at the same time under the condition that driving force provided by single vibration source .

2. Equipped with a new type of distribution device, the material passes through two buffer guide plates to reduce the flow rate to achieve initial distribution, and then passes through a distribution grid for uniform distribution to solve the problem of uneven distribution of materials.

3. The screen surface support structure adopts arc design, so that the material can be distributed for the second time, further improving the probabilityof the material contacting the screen surface and contact time , to improving the screening effect.

4. The inclined cylindrical shearing rubber spring is used in conjunction with the auxiliary vibration vertical rubber spring. By adjusting the stiffness of the shearing spring and the supporting spring, the working load of the shearing spring is reduced and the operation reliability of the screening machine is improved.

5. Multiple screen boxes are arranged, and the screen surfaces of each layer are independently fed and screened independently; multiple channels are connected in parallel, and the maximum screening capacity can be obtained with small footprint.

6. The screen frame is supported by special shearing springs, with low noise, low power consumption, small dynamic load of the equipment, and no special requirements for installation.

7. The main body of the screen machine is riveted with rivets and sprayed with a polyurethane protective layer to ensure the reliability and stability of the long-term operation of the equipment.

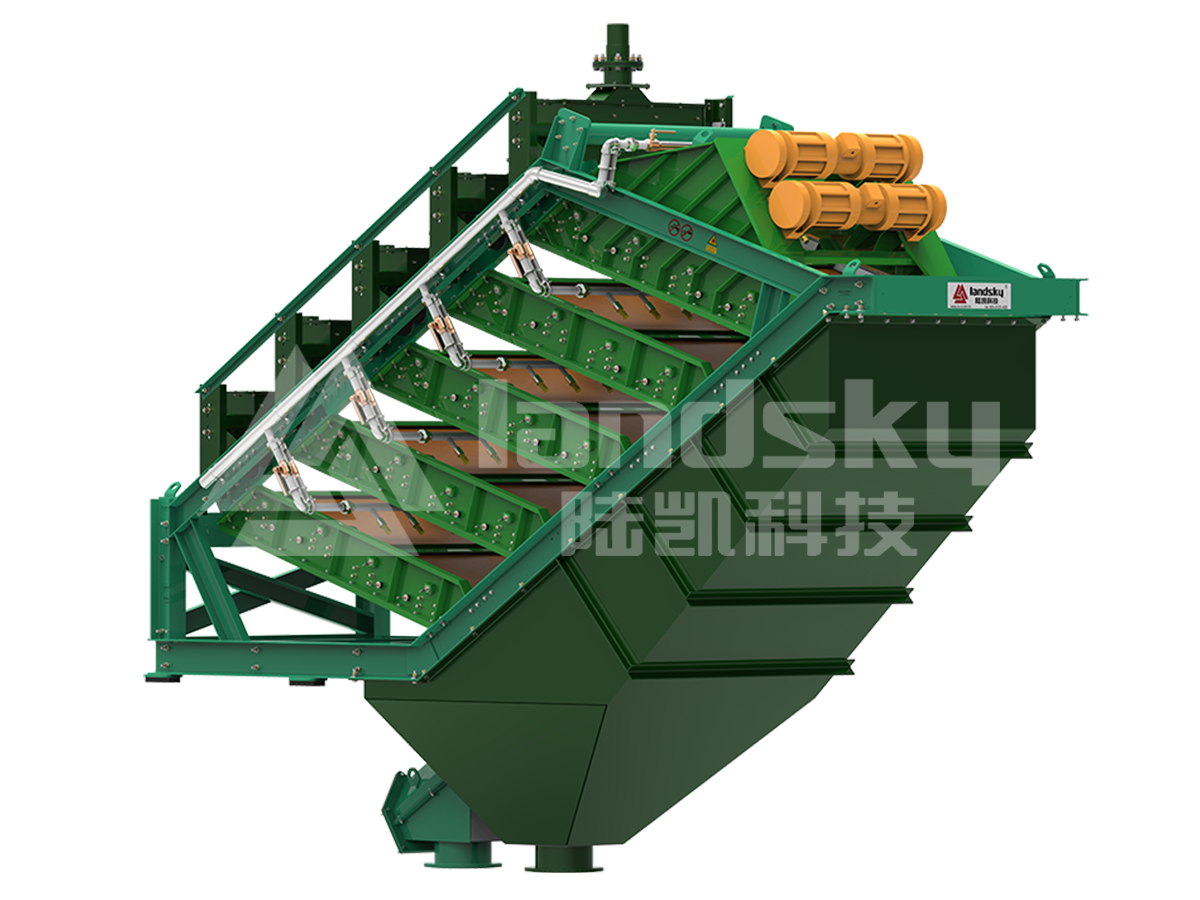

TECHNICAL FEATURES

1. The screen box vibrates linearly, and the vibration excitation frame inside the screen box is elastically connected in the screen box, and is driven by the screen box to perform secondary near-resonant vibration. It realizes two vibration types which are linear vibration and excitation frame resonance self-cleaning vibration at the same time under the condition that driving force provided by single vibration source .

2. Equipped with a new type of distribution device, the material passes through two buffer guide plates to reduce the flow rate to achieve initial distribution, and then passes through a distribution grid for uniform distribution to solve the problem of uneven distribution of materials.

3. The screen surface support structure adopts arc design, so that the material can be distributed for the second time, further improving the probabilityof the material contacting the screen surface and contact time , to improving the screening effect.

4. The inclined cylindrical shearing rubber spring is used in conjunction with the auxiliary vibration vertical rubber spring. By adjusting the stiffness of the shearing spring and the supporting spring, the working load of the shearing spring is reduced and the operation reliability of the screening machine is improved.

5. Multiple screen boxes are arranged, and the screen surfaces of each layer are independently fed and screened independently; multiple channels are connected in parallel, and the maximum screening capacity can be obtained with small footprint.

6. The screen frame is supported by special shearing springs, with low noise, low power consumption, small dynamic load of the equipment, and no special requirements for installation.

7. The main body of the screen machine is riveted with rivets and sprayed with a polyurethane protective layer to ensure the reliability and stability of the long-term operation of the equipment.

APPLICATION

Widely applicated in metallurgical mining, coal, non-ferrous metal and other industries, with high efficiency and perfect performance, and gains good reputation among the users.

Roy Hill Iron Mining(Australia)

Ore:Iron tailings

Process:Tailings classification

Model:D5Z1014

Qty:40 off

PhosAgro phosphate mining

Ore:Phosphate

Process:Closed circuit classification with Ball Mill

Model:D5Z1014

Qty:70 off

Xingtai Mining Industry Group (Jizhong Energy)

Ore:Coal

Process:Desliming and de-ashing coarse coal slime

Model:D5Z1021

Aperture size:0.25mm

Yunnan Chihong Zn&Ge Co., Ltd

Ore:lead-zinc

Process:Closed circuit classification with Ball Mill

Model:D5Z1021

Aperture size:0.12mm

APPLICATION

Widely applicated in metallurgical mining, coal, non-ferrous metal and other industries, with high efficiency and perfect performance, and gains good reputation among the users.

Roy Hill Iron Mining(Australia)

Ore:Iron tailings

Process:Tailings classification

Model:D5Z1014

Qty:40 off

PhosAgro phosphate mining

Ore:Phosphate

Process:Closed circuit classification with Ball Mill

Model:D5Z1014

Qty:70 off

Xingtai Mining Industry Group (Jizhong Energy)

Ore:Coal

Process:Desliming and de-ashing coarse coal slime

Model:D5Z1021

Aperture size:0.25mm

Yunnan Chihong Zn&Ge Co., Ltd

Ore:lead-zinc

Process:Closed circuit classification with Ball Mill

Model:D5Z1021

Aperture size:0.12mm

Related products

Service message

Create excellence with professionalism, pursue refined product design, advanced manufacturing technology and efficient and high-quality service

Contact details

Tangshan Headquarters

Mail: landsky@lk-t.com.cn

Tel.:(+86-315)3853380/3853381

Beijing office

Tel.:(+86-10)82610633/82618600

Shanghai office

Tel.:+86-13901678980

Language

Language

+86-13613155238

+86-13613155238

E-mail

E-mail